Contact application tailored to cover leaf target

Applying a contact fungicide is a key component of protecting turf from disease infection over high risk winter periods. Application technique can have a significant effect on getting the best possible results, reports Syngenta Technical Manager, Glenn Kirby.

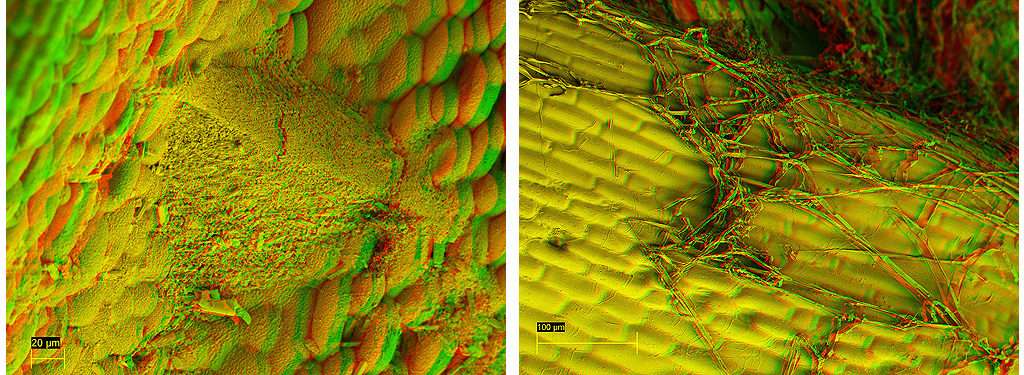

Contact fungicide treatment needs to achieve as complete a coating as possible on the leaf surface. This is essential to prevent disease spores germinating, and limiting hyphae penetration into stomatal openings or damage wounds, such mowing or walking on a frosty surface.

Unlike with a systemic product, where there is some flexibility for the fungicide active to distribute through the plant from leaf, crown or even root uptake, for contact protection the application technique is essential .

Often when making an application there can be a mix of products in the tank with a range of objectives and target points; the application technique selected should then be a conscious compromise, to balance achieving the desired results and the practicality of getting the job done.

However, with the essential role of a winter contact fungicide, it is one treatment that typically needs to take priority, and every effort made to get the best possible result with leaf coverage. If you are applying a contact fungicide, it will be at a critical phase in your disease management program and definitely not the time to be compromising.

Contact products are crucial during periods of slow growth, since there is little or no opportunity for systemic actives to move around in the plant – particularly with the loss of propiconazole, which was still mobile at relatively cool temperatures, and iprodione that was a local penetrant into the leaf surface layer.

That leaves just fludioxonil, which is the active ingredient in Medallion TL and a key component of Instrata Elite, as the remaining contact active fungicide.

The optimised product formulations will help spray droplets to stick on the leaf, as well as to spread and coalesce across the surface. But using the right nozzle, water volume and operating pressure will improve the chance of achieving the desired result.

Application research trials by STRI have used Ryder turf pigment as an assessment of leaf coverage, with the colour intensity providing an excellent indicator of how contact fungicide applications could also perform.

Results showed up to 18% improvement in turf colour with application using a Syngenta XC 04 nozzle, compared to an industry standard high-performance drift reduction nozzle, for example. For evenness, the XC nozzle outperformed an existing 90% drift reduction nozzle by 22%.

Whilst all nozzles produce a range of droplet sizes, operators can tip the balance in favour of leaf retention with a higher proportion of smaller droplets. When the average diameter of a droplet is halved, the number of drops increases by a factor of eight, which can help with more effective coverage of the surface.

Furthermore, a smaller nozzle, such as 025, typically produces a far greater proportion of smaller droplets that can be better retained on the leaf. An 04, at the same pressure, produces a greater proportion of small to mid-sized droplets, which are good for leaf coverage, but some will also reach down to the crown and thatch.

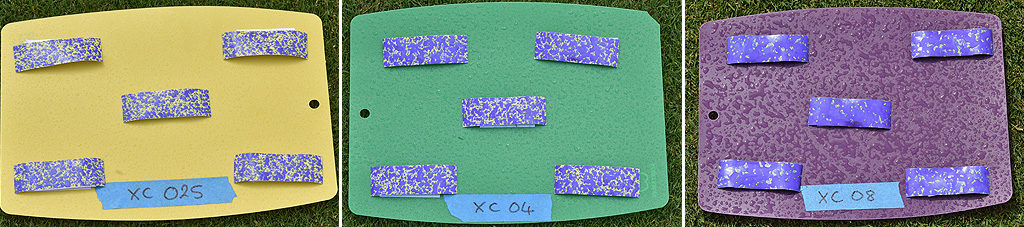

Coupled to the nozzle size, is the operator’s selection of water volume, forward speed and sprayer pressure. It is important to apply sufficient water volume to give the desired coverage, typically 250 to 400 l/ha, but not so much as to over wet the leaf surface and lead to run off .

Syngenta application research, using water sensitive paper to assess coverage from different nozzles, clearly shows the effect of small droplets from an 025 nozzle (left), designed to give good coverage and retention on the leaf surface, compared to an 04 (centre) where larger drops begin to run together to also give good coverage, but where an 08 would over wet the surface and result in significant run off from the leaf.

Tight cut greens offer very little leaf surface area to hold spray on the leaf, without losing it to run-off. Even easing off cutting height from three to five mm in winter, for example, will present a bigger target to hold spray coverage. Raising the height of cut will also alleviate some stress on the plant, as an effective Integrated Turf Management practice to reduce disease risk.

With smaller nozzles, such as the 025 XC Nozzle (below) operators will have to select a slower speed to apply a set water volume, operating at two to three bar, compared to a larger nozzle orifice. Operating slower does have an advantage in reducing turbulence associated with faster speeds, which could impact on even coverage. Furthermore, boom stability is vastly improved at slower speed, to maintain a level 50 cm above the target.

There is also often the temptation to increase speed on long straight runs and slow down at the ends, particularly with an auto-rate controller that will automatically maintain the consistent spray application rate. The problem is that as speed increases, so the pressure ramps up to apply maintain consistent sprayer output, and that inherently changes the nozzle performance, to create far more droplets susceptible to drift.

Smaller spray droplets produced at higher pressure are particularly difficult to control and hit the target. That can be a serious issue for environmental loss, but even spray movement along the boom in a gust of wind could also affect consistent coverage for a contact fungicide.

Given the importance of the winter contact fungicide, it is worth committing some effort too with nozzle selection and operation to optimise targeting application.

Recommendations for optimum targeting of foliar contact fungicide application would be: | ||||

Area | Nozzle choice | Water volume | Pressure (bar) | Speed (km/hr) |

Greens | XC 025 | 200 – 300 | 2.0 – 3.0 | 4 - 5 |

Fairways and sports turf | XC 04 | 220 – 380 | 2.0 – 3.0 | 5 - 7 |

Application Academy

To further enhance your application knowledge, register now for a chance to join an unrivalled education opportunity at the pioneering Syngenta Application Academy. Get the opportunity to learn the science behind spray technology from leading industry specialists, along with in-depth practical skills required to become a top sprayer operator. Applications for the 2020 Academy close mid-February – but you can still register for future events.

Read all of the Greenkeeper International Insight features here