Sprayer set up for accurate application

Golf courses present one of the greatest challenges for sprayer operators.

Undulations that make for an interesting course design can seriously compromise boom height and stability, which adversely affects the spray pattern. While a tight turf surface, cut at just 2.5 – 20 mm, gives limited leaf area to trap and hold the spray droplets – resulting in increased risk of drift and spray missing the intended target.

Syngenta EAME Technical Manager, Glenn Kirby, offers advice on sprayer set-up to achieve the best possible results from every application.

Accurate application can typically account for over 30% of the performance of any treatment, but at its worst could result in almost no beneficial effects, or visible stripes of over or under application – particularly with nutrition or pigment treatments.

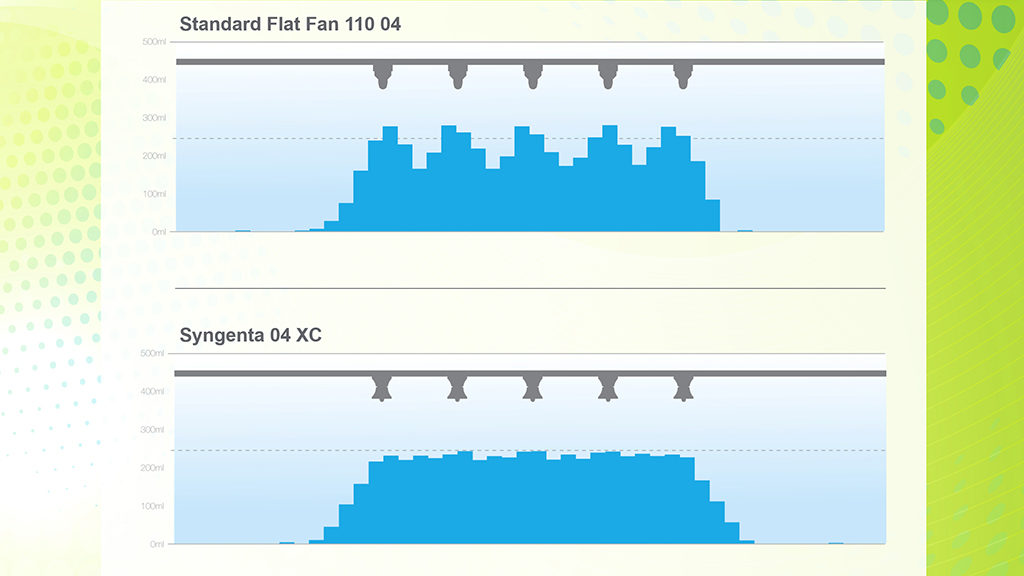

Maintaining an even spray pattern is the first crucial step in achieving consistent coverage of the turf surface.

Sprayer nozzles are typically designed to give an even overlap and coverage operated at a height of 50cm from nozzle tip to the target. Where nozzle fittings can sit 5 – 10 cm below the boom, it is important to measure from the nozzle tip to the target.

The main concerns are typically undulations on a McKenzie style green, around perimeters where bunker mounding forms part of the green complex, or steep inclines up onto or off the green. If, for example, the boom pivots over an undulation it’s not uncommon for one end of the boom to dip to 10cm, whilst the other end rises to 90cm. At both ends, the pattern could be 75-80% different to the 50cm standard. Excessive boom height also significantly increases the level of drift.

The faster the forward speed of the sprayer, the more boom movement typically occurs – which can be alleviated by simply reducing speed, providing the water volume application rate is not compromised.

Regular sprayer maintenance, with attention to the boom pivot and any damping system, will also help to mitigate effects; also check the boom is level across its full width during operation.

Effects of undulations and boom movement are most severe at either end of the boom, and the bigger the sprayer the greater the potential problems. If areas of the course, or a particular green, prove especially troublesome, operating just the central section of the sprayer behind the most stable part can achieve more consistent results.

Issues with a rear-mounted sprayer on slopes and inclines can be exacerbated the further the boom sits behind the rear axle, which acts as the pivot point; sprayers mounted on a utility vehicle are typically less affected than tractor mounted sprayers where the boom is offset behind the tank. However, on some utility mounted sprayers it can be difficult to set the boom sufficiently low for nozzle tips to be 50 cm from the surface.

One simple aid is to fit a cable tie nozzle height indicator to each end of the boom, cut off so that the end brushes the ground when the nozzles are operating at 50 cm. It is particularly useful when lowering hydraulically controlled booms to the correct height, but also as a guide during operation if nozzle height has been compromised.

Some nozzle designs are more susceptible to variability of boom height than others, particularly conventional flat fan nozzles.

The development of the Syngenta XC Nozzle was designed to give more consistent pattern and coverage at heights as low as 30 cm, specifically to improve accuracy on golf course applications (Fig 1).

Spray drift could cause a significant proportion of the application to never reach the intended target – with obvious consequences for results. Faster forward speed and too high a boom height will both have an impact on turbulence and movement that could result in spray drift. But the biggest factor is the spray droplet size, with finer droplets more susceptible to drift.

The physics of spraying mean there is a curtain of droplets descending from the nozzles, which need to move the air between the boom and the ground out of the way for the droplets to reach the surface target. In a field of crop, or longer turf, there is more room for air to be pushed out of the way and effectively pull the spray among plants; with short, dense fine turf it is more difficult for the air to move away, which significantly increases the risk of drift.

Larger droplets, with greater energy, can successfully break through the air and descend, however finer droplets are slower to fall and more susceptible to any side movement and loss as drift. In practice, a proportion of fine droplets may never even reach the target surface.

This can be made even worse of spraying during inversion conditions – when cool air sinks and sits as a layer at ground level, with warmer air above. Fine droplets can be trapped between the layers and left hanging, like fog, without reaching the ground. Inversion conditions are typically encountered when spraying early in the morning or late in the evening, as frequently occurs on golf courses.

With any nozzle increasing operating pressure to apply a higher water volume will also result in producing a higher proportion of more drift susceptible finer droplets. To apply a water volume of 500 l/ha through an 04 nozzle, spraying at 4.5 km per hour, would require a pressure in excess of 4 bar – well above the optimum 2 – 2.5 bar that would minimise drift risk. Reducing the water volume used to 390 l/ha would enable the pressure to be cut back to 2.5 bar. Alternatively, slowing down from 4.5 to 3.5 km/hr would enable application of 500 l/ha operating at 2.5 bar.

It's this balance between speed and operating pressure that needs to be calculated for nozzle size selection.

It is also essential to understand where auto-rate controllers are fitted on the sprayer, since any increase in speed will automatically raise pressure to maintain application of the selected water volume.

If you had set up to apply a water volume of 280 l/ha at 3.5 km/hr with pressure at an optimum 2 bar, but then raise speed to 5 km/hr the pressure would increase to over 4 bar to compensate – resulting in a huge plume of spray drift.

Just a small reduction in droplet size can have a dramatic effect on the number of droplets and the increased risk of drift missing the intended target.

When you halve the diameter of a droplet size, then number of smaller droplets for the same water volume is eight times greater.

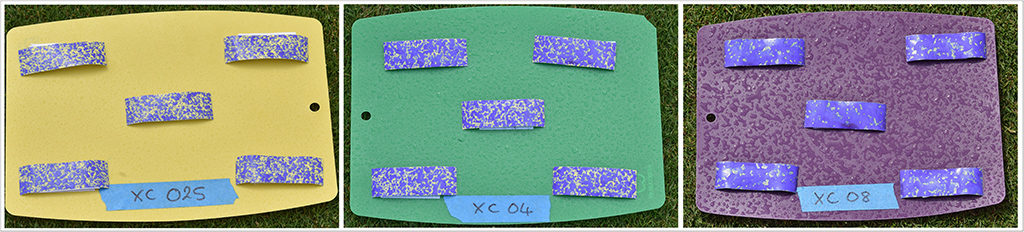

All nozzles produce a range of droplet sizes, from ultra-fine to extra-coarse. However, the proportion of each droplet size is influenced by the nozzle orifice size, the nozzle design and its operation. A small orifice conventional flat fan nozzle, such as an 025, will produce a very high proportion of small droplets and small number of coarse droplets, compared to an 08.

Furthermore, with nozzle design, an air induction 04 will produce consistently more medium to coarse size droplets that are less susceptible to drift, compared to a flat fan 04.

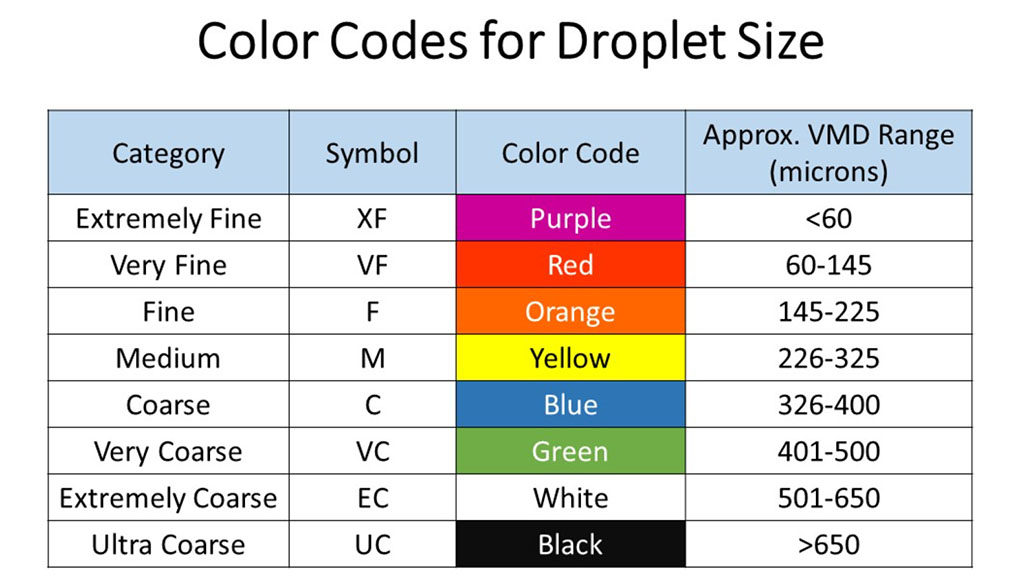

The range of droplets produced by any nozzle is measured as a coefficient of variation, with the aim to have a higher proportion of the desired size and fewer at either extreme. Nozzles are classified in eight stages, from extremely-fine, through medium, coarse and up to ultra-course – according to the volume median diameter of the droplets it produces, whereby half the droplets are smaller and half larger (Fig 2).

Smaller droplets are more susceptible to drift, with anything classified as very fine (145 microns or less) particularly prone to sideways or upward movement in air currents. Clearly wind speed is a major factor with drift, but operators should be aware of gusty windy conditions that can quickly shift the spray pattern sideways, resulting in uneven coverage and potential patchy results.

Syngenta XC Nozzles are an air induction design, which incorporates air into each droplet that makes it significantly larger and with greater energy to reduce the risk of drift. It also acts as a shock-absorber when it hits the leaf to ensure better retention, compared to an equivalent size droplet from a conventional nozzle that is more liable to bounce or roll off the waxy coating of turf leaves.

XC Nozzles produce up to four times more more drops per ml, compared to other air induction nozzles, that makes them particularly well suited to turf applications. They also include an integrated angle to deliver more even coverage on the front and back of the leaf surface, by compensating for the forward movement of the sprayer. The angle is different for each of the 025, 04 and 08 size nozzles available, from 4.5⁰ to 9⁰ independently assessed to be optimised for turf leaf coverage.

The turf-specific design was a major step in enhancing golf course application by enabling more consistent coverage on undulations and inclines, as well as reducing risk of spray drift – typically by 75% compared to a conventional flat fan nozzle. New research continues to assess and develop further advances in nozzle technology, that offers the potential for 90% drift reduction in the future, while maintaining or improving results.