GDD – What’s your number?

Growing Degree Days is now recognised as a highly effective tool to achieve consistent control of turf growth.

Fortunately, it’s not a lottery to pick a winning number for GDD, writes Syngenta Technical Manager, Glenn Kirby. Thanks to a huge volume of scientific research - globally and direct in the UK – it has been established that a GDD of 200 - when using base figure of 0⁰C (find out more below) - is a great target on which to base the timing of a Primo Maxx II application programme.

It is important, since a survey of over 250 greenkeepers identified consistency of playing surface throughout the day as the No.1 benefit of a PGR programme. Maintaining that over a period of time, with consistent levels of growth control can be difficult without maintaining turf in consistent regulation between applications.

Calculate your GDD now - click here to try

PGRs that work by supressing gibberellic acid production in the plant concentrate the energy from photosynthesis into carbohydrate reserves – which is perfect for root production and turf density. But, if the interval between applications is too long, the suppression effect is released and the pent up-energy results in a surge of growth – the ReBound effect.

GDD is particularly effective because it uses temperature to track the duration that the PGR will maintain its effect on the turf plant. In cool conditions the positive effect lasts longer, so the application interval can be extended; in warmer temperatures the PGR effect will degrade more quickly and so the application interval needs to be closer.

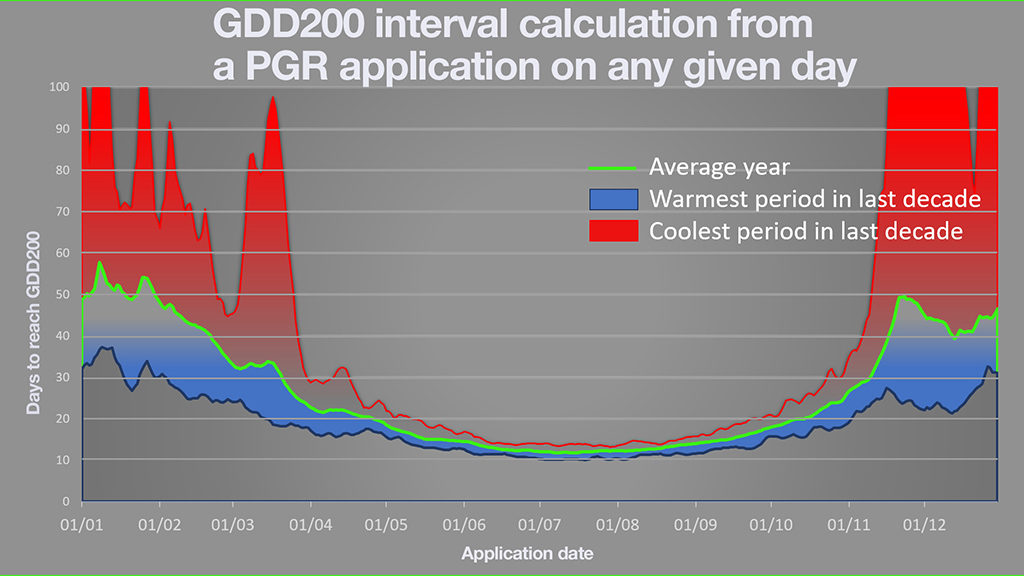

A study of temperatures in the UK (Fig 1.) has shown that through the early spring and at the end of the season in autumn, application intervals at GDD200 could, on average, be over a month apart – shown by the green line.

However, from mid-April through to mid-October the application interval would need to be less than 21 days to optimise growth control. From mid-May to mid-September the GDD200 model demonstrates that 10 to 14-day applications are necessary to keep turf in regulation.

It warns that any PGR product programme that extended intervals beyond 15 to 17 days in the growing period would be liable to periods of no growth suppression.

It would even risk the potential for growth to rebound even greater than it would have been without a PGR application throughout that summer period – even in the coolest years recorded over the past decade.

Consistent results

Applying PGR on a routine 14; 21 or 28-day programme is impossible to achieve the optimum level of consistent turf growth control, particularly in variable conditions. In some instances, it could be leading to wasteful over application, or at other times plunging turf plants in and out of regulation.

If a GDD model is not used, observational monitoring of grass clipping yield can highlight when the effects are beginning to wear off and trigger reapplication. It does require carful record keeping and, if weather conditions were to prevent application, potentially lead to an extended interval.

Using a GDD model, it can be tracked daily when a treatment timing is approaching. That can be matched to forecasts of spraying opportunities to ensure application is covered, or to incorporate with another spray of nutrition or wetting agent, for example, to simplify operations.

Adjusting intervals

Whilst the GDD200 has been shown to be a good starting point for most Primo Maxx II programmes, experience will indicate how that might be tweaked to best match any specific site’s growth or individual’s desired levels of growth control.

A high-fertility, parkland setting, for example, may find a GDD180 better suits the level of consistent growth control required, compared to another site where a GDD220 may deliver precisely the level of regulation desired for that course.

The key to consistency is that once the GDD interval has been established, it works throughout the season and adjusts the frequency of application accordingly. If the interval is 10 to 14 days in summer, the programme needs to be selected accordingly.

Guide timings

Another positive of using a GDD model is that it does help to guide application timings according to the individual season’s conditions. It is clear from the data in Fig 1. that over the summer, intervals are typically more consistent year-on-year. At the start and end of the season, however, there can be far greater variation.

In practice, using GDD for product application intervals is somewhat different to assessing grass growth potential, for example. In the past the UK has typically used a base of 6⁰C in calculating GDD that reflects the temperature at which growth commences and a simplistic picture of periods of growth.

However, using that model tends to lead to hugely protracted GDD periods from mid-autumn through to late spring. Now, new thinking shows that if the base temperature is set to 0⁰C for product interval timing, there is a much closer correlation to how they work in the plant and the realistic expectation of what can be achieved. The information in Fig 1 is calculated on the 0⁰C base temperature.

Calculate your GDD now - click here to try

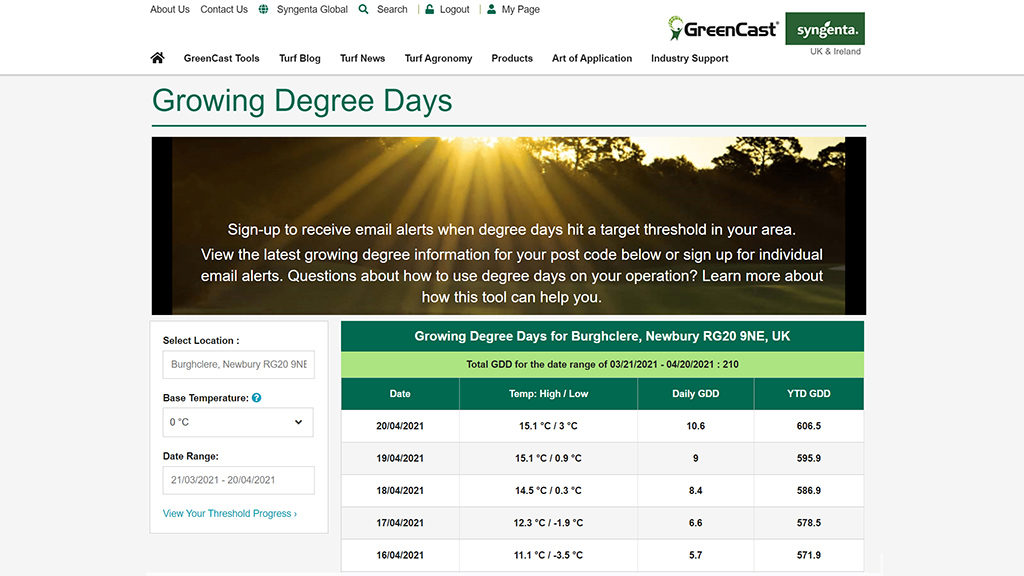

The free on-line GreenCast GDD Calculator now gives the option to instantly view results for any course location with a 0⁰C; 6⁰C or 10⁰C base. The figures are automatically generated from weather record data, so there is no need to input any further information.

It can also be set to generate emails alerts of impending GDD targets, to better plan actions and applications.

For PGR applications the use of GDD enables far greater precision in interval timing to assure consistent results.

Read all Glenn Kirby's previous Greenkeeper International features here